Cemented carbide mold use and classification

Cemented carbide molds are ten times or dozens of times longer than steel molds. Cemented carbide molds have a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high Hardness and wear resistance remain basically unchanged even at a temperature of 500°C, and still have a high hardness at 1000°C.

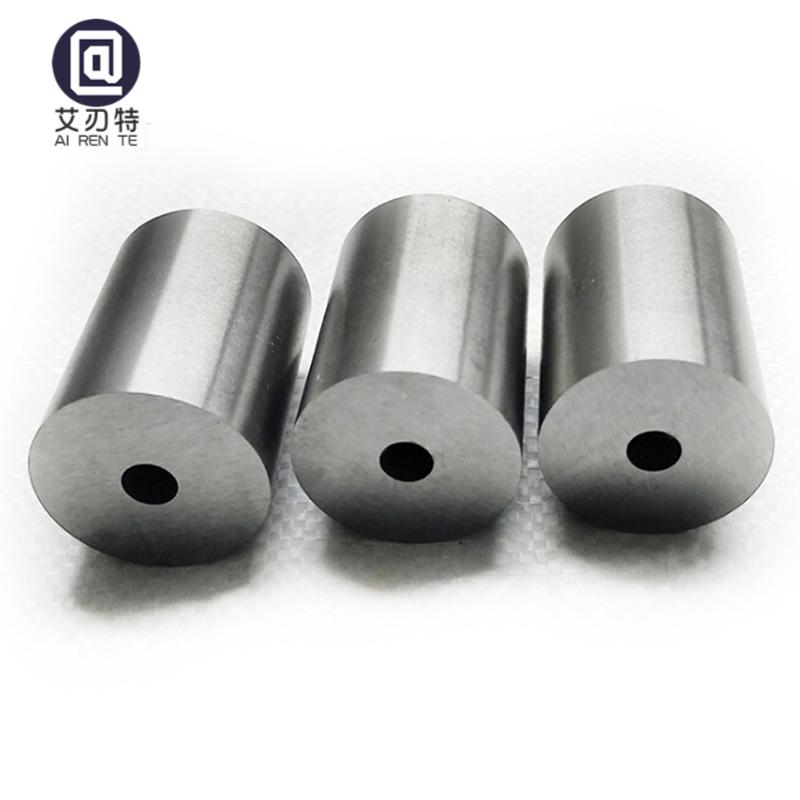

Our standard materials: YG6, YG8, YG11, YG15, YG11C, YG16C, YG20C, YG25C, YG6X, etc.Using primary tungsten carbide material, using isostatic pressing and low pressure sintering process, the cemented carbide mold products have good toughness and wear resistance, and the service life will be increased by 3 to 5 times.

Cemented carbide molds mainly include standard bolt upsetting die, bolt upsetting die, countersunk top die, hexagonal nut cold heading die, steel ball die, battery die, hexagonal nut block die, taper straight hole punching die, outer cone Straight hole punching die, cemented carbide peeling die, cemented carbide scissor blade, cemented carbide drawing die, cemented carbide sealing ring, cemented carbide roll, etc.

Zhuzhou Aite Cemented Carbide Co., Ltd

Zhuzhou Aite Cemented Carbide Co., Ltd