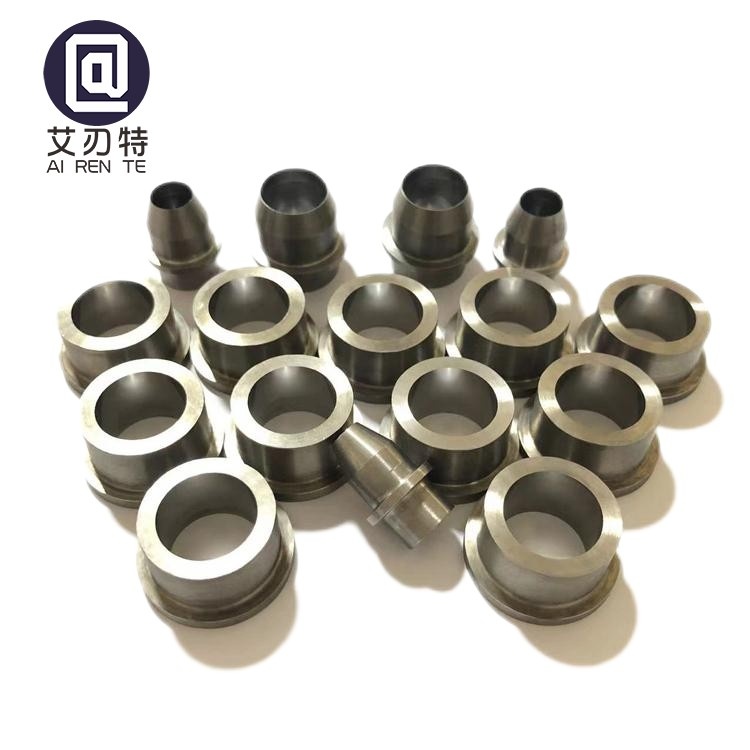

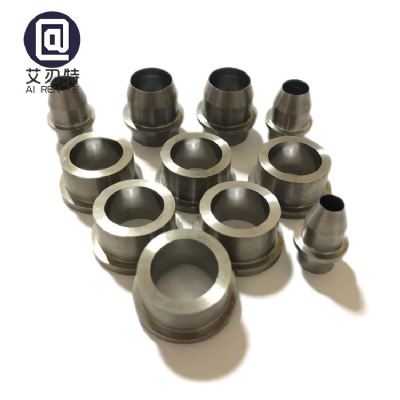

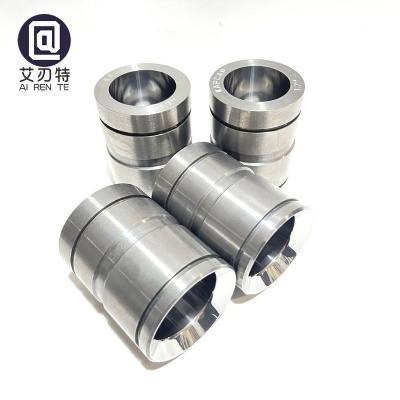

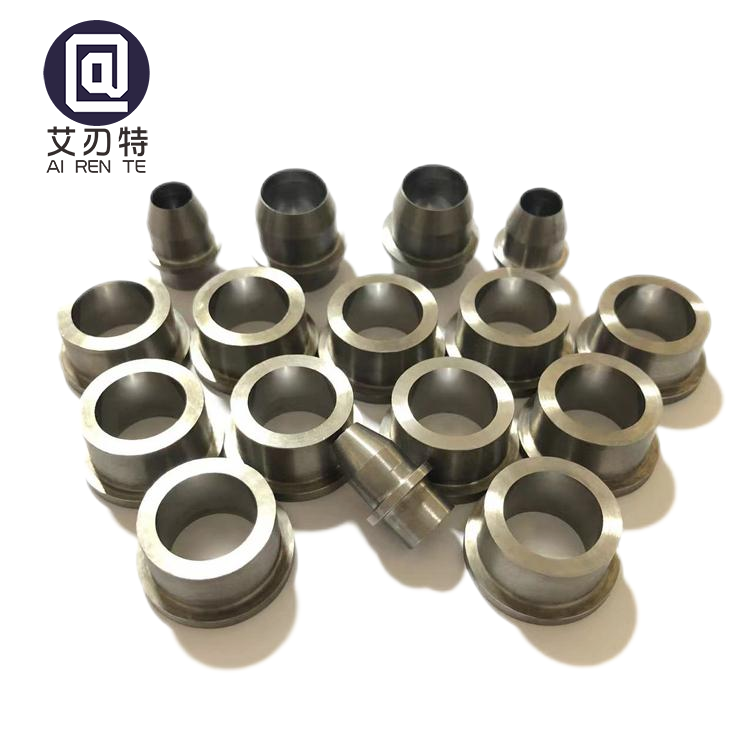

Zhuzhou Aite Cemented Carbide Manufacturing provides customized tungsten steel valve seats, tungsten steel valve sleeves, tungsten steel valve cores, tungsten steel bushings, tungsten steel guide sleeves and other precision tungsten steel sleeves, specializing in the use needs of oil and gas machinery operations.

As the main objects of geological exploration, scientific and effective oil and gas extraction process is an inevitable requirement for social and economic development. The sealing tungsten steel valve seat and tungsten steel valve sleeve made of tungsten steel material precision processing have high hardness, high density, high strength and stable chemical properties as well as good bending strength and impact toughness, which makes the performance of tungsten steel valve seat in improving oil drilling oil pump surpass other material choices. The excellent wear resistance and corrosion resistance improves drilling efficiency, prolongs the service life of tools, and reduces working costs.

Our advantages: Zhuzhou cemented carbide professional manufacturer, providing precision tungsten steel processing non-standard customization.

There are many different choices in diameters, lengths and grades, which could all be manufactured according to clients' special requirements. Therefore, if you have interest in buying Carbide valve seat/carbide valve sleeve, please do not hesitate to e-mail us with your specific requirements to : [email protected]

Zhuzhou Aite Cemented Carbide Co., Ltd

Zhuzhou Aite Cemented Carbide Co., Ltd