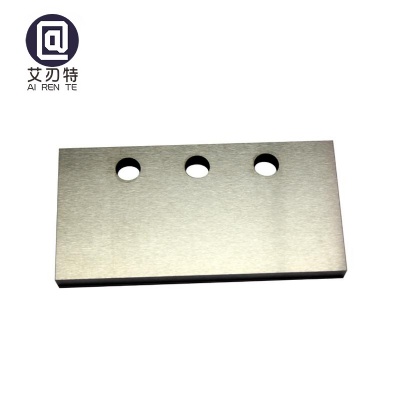

4.Suitable for making stamping dies (processing silicon steel sheets), wear-resistant parts, etc.

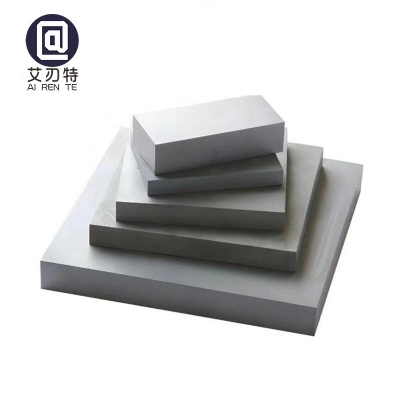

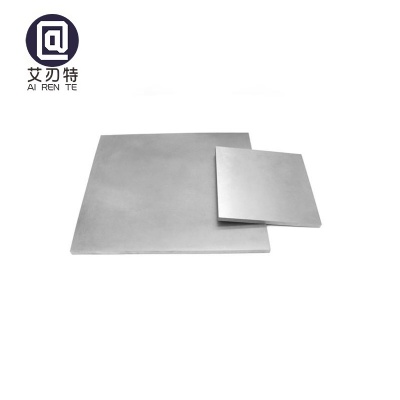

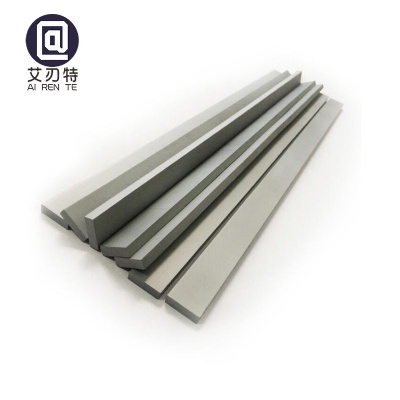

Here below are the specifications of tungsten cemented carbide bars we always offered:

|

Length(mm) |

Wide(mm) |

Height(mm) |

|

40 |

40 |

2~20 |

|

50 |

50 |

2~20 |

|

60 |

50 |

2~20 |

|

100 |

85 |

2~15 |

|

100 |

100 |

2~70 |

|

105 |

105 |

2~70 |

|

120 |

120 |

3~70 |

|

150 |

100 |

3~70 |

|

150 |

150 |

4~70 |

|

200 |

100 |

4~70 |

|

200 |

200 |

3~70 |

|

250 |

130 |

3~70 |

|

250 |

150 |

3~70 |

|

250 |

200 |

3~70 |

|

250 |

250 |

3~70 |

|

270 |

120 |

3~70 |

|

300 |

160 |

3~30 |

|

300 |

200 |

3~30 |

|

300 |

250 |

3~30 |

|

320 |

215 |

3~30 |

|

350 |

250 |

3~30 |

|

...... |

...... |

...... |

There are many different choices inlengths and chemical compositions, which could all be manufactured according to clients' special requirements. Therefore, if you have interest in buying tungsten carbide plates, please do not hesitate to e-mail us with your specific requirements by : [email protected]

Zhuzhou Aite Cemented Carbide Co., Ltd

Zhuzhou Aite Cemented Carbide Co., Ltd